OXYION® MDBD technology delivers a unique biosecurity enhancement that modulates electrical variables through a Modulated Dielectric Barrier Discharge (MDBD). Its primary function is to support the reduction of environmental contaminants safely for people and the environment. This process requires no added chemicals and leaves no residual compounds, offering a clean, complementary approach to improving indoor air quality.

The continuous, self-pulsing plasma process optimizes the production of oxygen-based byproducts, including gas-phase hydrogen peroxide (H₂O₂), while preventing the formation of nitrogen derivatives.

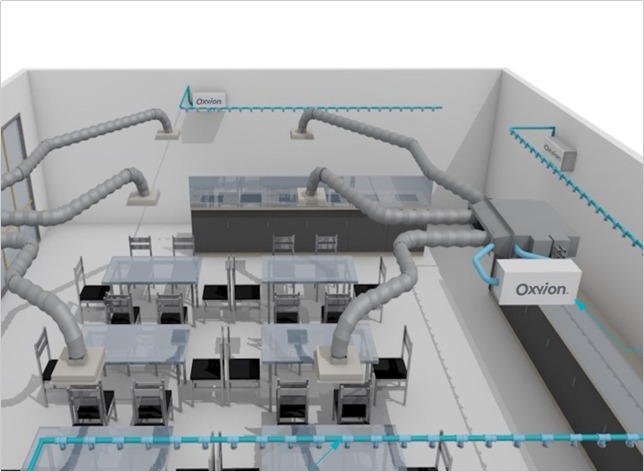

Oxyion technology can be seamlessly integrated with existing air handling systems or deployed as a standalone solution, helping reduce environmental contaminants without relying solely on conventional air filtration.

Scientific Research

Oxyion rapidly neutralizes harmful biological agents:

Coronavirus in minutes

Norovirus and Rhinovirus in 30 minutes

of Listeria and mRSA in 2 hours

Benefits:

Effective

Proven Safe Technology for any occupied indoor space

Safe for people

(no chemicals, no residues)

Continuous protection

24/7 air and surface sanitization, operating safely during all processes while people are present.

No downtime

Automatically setup through a controller, no operator required.

Flexible solution

A complete solution for air and surface treatment, addressing viruses, bacteria, mold, and other contaminants with a single system—without the need for multiple formulas or added chemicals.

Preventive

Operates seamlessly from day one, requiring only low electrical power, ambient air, and the support of our comprehensive seasonal plan.

Strong Worldwide Presence

With over 20,000 installations across the Americas and beyond, Oxyion and its licensed brands are trusted worldwide.

INTERNATIONALLY RECOGNIZED CHEMICAL-FREE TECHNOLOGY

Approved sanitizer/disinfectant process with no use restrictions, compliant with USDA National Organic Standards and recognized by leading international organic certification bodies.

Oxyion offers a clean technology approach to support the management of indoor environmental contamination.

Oxyion powered systems are designed to strengthen indoor air quality in spaces such as offices, break rooms, industrial cooling, and processing areas. Our technology supplements existing cleaning practices by continuously reducing levels of airborne and surface microorganisms, including bacteria, mold, and other contaminants. It achieves this by generating safe oxygen byproducts from ambient air, which interact with these agents and help lower their presence in treated areas.

Our solutions can be adapted to a wide range of applications—from small, independent units for common spaces to large-scale systems for industrial settings. Each project includes an engineering review of the air handling/HVAC layout to provide a tailored implementation plan. Installations can be completed by any licensed contractor or HVAC professional.

Oxyion is intended as a complementary measure to existing hygiene, cleaning, and sanitization protocols. Systems operate safely during normal activity without downtime, providing consistent, continuous support in reducing microbial load in indoor environments.

Provides continuous supplemental reduction of airborne and surface microorganisms (including bacteria, mold, and other environmental contaminants) in common areas, cooling rooms, holding rooms, processing, and post-process environments.

Operates without added chemicals and is designed to be safe for use in occupied spaces.

Provides continuous supplemental reduction of airborne and surface microorganisms (including bacteria, mold, and other environmental contaminants) in common areas, cooling rooms, holding rooms, processing, and post-process environments.

Operates without added chemicals and is designed to be safe for use in occupied spaces.

Continuous microbial reduction process

Independently Tested & Proven technology

Oxyion technology has been scientifically evaluated in more than 100 independent and company-supported studies across the Americas and internationally, demonstrating its ability to safely and effectively help reduce levels of microorganisms such as bacteria, mold, and other environmental contaminants in indoor spaces.

With over 20,000 installations deployed under the Oxyion and Airlife brands in public facilities and industrial environments, our technology has consistently shown real-world performance in supporting cleaner indoor air and surfaces.

Continuous Environmental Quality Approach

Assessment

- Site evaluation and measurement.

- Review of areas identified for treatment, including floor plans, diagrams, climate project CAD files, and mechanical drawings.

- Determination of cubic footage for indoor spaces requiring coverage.

- Recommendation of equipment configuration tailored to the application (biosecurity / food quality support).

Intervention / Application Phase

- Design and implementation of the recommended configuration for selected indoor spaces. Equipment can be deployed while spaces remain occupied, without disrupting ongoing processes or altering standard operating procedures. Systems may be integrated with existing HVAC or installed in walls/ceilings, offering flexibility to place purification units where they are most effective.

- Activation and commissioning of Oxyion equipment for continuous supplemental reduction of airborne and surface microorganisms—implementation can be completed in as little as 24 hours, depending on facility needs.

Continuous Support / Preventive Control Mode

- Oxyion-powered equipment operates continuously (24/7) to help maintain improved indoor environmental quality through consistent microbial load reduction.

- Tailored service programs are available, including extended warranties on parts to ensure optimal system performance.

- Smart control systems include software with dynamic operation capabilities, giving users flexibility to adjust equipment settings through virtual management tools.

Continuous remediation and prevention approach

Assessment

- Assessment/ measure

- Analysis of areas in need of treatment, floor plan, diagrams, climate project CAD files / mechanical drawings for Building and indoor areas.

- Cubic footage of indoor spaces that require protection.

- Recommendation for equipment configuration based on the application (biosecurity/food safety)

Intervention / Application phase

- Design and implementation of recommended configuration applied to the selected indoor spaces. Equipment can be implemented while people are present without affecting the process or altering the standard operating procedures. Systems can be installed by the HVAC systems or in walls/ceiling with the flexibility of mounting the purification units where they are needed.

- Activation and startup of Oxyion equipment for continuous reduction and neutralization of microbial/viral loads, can be implemented in as little as 24 h depending on facilities.

Continuous improvement/preventive control mode

- Oxyion equipment operates continuosly (24/7) to maintain clean enviroments with a proactive inactivation of harmful biological agents.

- We provide tailored service programs with extended warranty on parts for optimal equipment performance.

- Oxyion smart control systems incorporate software that has dynamic operation capabilities and allow the user the felixibility to easily adjust equipment with virtual production management.

Our technology operates

without added chemicals, meets USDA National Organic Program standards (NOSB #2857), and functions within established OSHA worker safety guidelines.

Comparisons

Technology comparison

Oxyion is not UV technology that emits radiation—often limited in effectiveness for larger industrial settings—nor does it operate like ozone generators that rely on flooding a room with ozone. Instead, Oxyion produces a safe, chemical-free blend of oxygen-based byproducts, including gas-phase hydrogen peroxide, which are circulated through a facility’s existing air handling systems or HVAC. This process operates continuously to help reduce microbial load in indoor spaces and support cleaner environments for both public areas and perishable processing operations.

| Oxyion | UV-UVC | UV PCO PECo PHI | Bipolar Ionization | HEPA filters | Ozone gen, other ROS | |

|---|---|---|---|---|---|---|

| Virus, bacteria, mold control on Surfaces. 6+ ft. away from unit | Only close to UV device | Only close to ionizer | At unsafe levels | |||

| Virus, bacteria, mold control /AIR. 6+ ft. away from unit | Only close to UV device | Only close to UV device | Only close to ionizer | At unsafe levels | ||

| People exposure concerns | Unrestricted. continuous | UV Light radiation hazard | UV Light radiation hazard | Only close to ionizer | N/A | Hazard, ozone above limit |

| Specific Sanitization Process registry | USDA National Organic Standards #2857 | Generic | Generic | Generic | N/A | Generic |

| Safety | UV radiation concerns | UV radiation concerns | Exposed electrodes/ high voltage | N/A | Hazard: ozone levels above limit | |

| Active anti microbial Agents | 7 5 inside/ 2 outside system | 2 or 3 inside system only | 2 or 3 inside system only | none | N/A | 1 |

| Sanitization agents duration | several minutes | seconds | seconds | seconds | N/A | minutes |

| Ozone safe | N/A | |||||

| Smart control system | ON/OFF Switch only | ON/OFF Switch only | ON/OFF Switch only | N/A | Unreliable ozone sensors mostly | |

| Ethylene control | Only close to UV device | Only close to UV device | Only close to ionizer | At unsafe levels | ||

| Potential negative impact on HVAC | – | Oxidation close to unit | Oxidation close to unit | Oxidation close to unit | – | Oxidation to ducts |

| Energy efficient | May reduce energy costs | May reduce energy costs | Creates pressure drop | |||

| Level of service presence/structure | Certified technician network for service | Limited service. Parts need to be purchased for user replacement. | Limited service. Parts need to be purchased for user replacement. | Limited service. Parts need to be purchased for user replacement. | Filters | Limited service. Parts need to be purchased for user replacement |

Active Continuous Inactivation System

“Not all plasmas are created equal”

What Differentiates Oxyion Technology

Unlike passive purification methods, Oxyion technology generates a consistent and proprietary Modulated Dielectric Barrier Discharge (MDBD) plasma with prolonged, self-sustaining propagation. This allows oxygen-based reactive byproducts to remain active in the environment for extended periods—lasting hours compared to the much shorter lifespans observed in other approaches—providing continuous interaction with airborne and surface microorganisms.

The extended activity is achieved through Oxyion’s proprietary core power supply, which produces gas-phase hydrogen peroxide plasma with enhanced ion mobility. This increases the number of molecules carrying free electrons in higher-energy states, keeping them available for ongoing environmental interactions.

Oxyion’s controlled diversity contributes to sustained plasma viability and efficient supplemental reduction of microbial load across treated areas.

The Oxyion system consists of MDBD modules (HFM & SRM), which combine frequency- and voltage-modulated pulse circuits to drive a sealed dielectric barrier discharge chamber array. The process adapts dynamically to the environment without altering temperature or humidity.

Certified under the USDA National Organic Program as a chemical-free input (#2857), Oxyion operates with no added chemicals or residues. The plasma process collectively supports improved indoor environmental quality through continuous microbial load reduction.

Oxyion’s technology does not produce just one or two types of ions, but instead a full spectrum of seven specific sanitizing agents that together

results in longevity of plasma viability driving superior outcomes in a shorter timeframe than results purported by competing technologies. Additionally, Oxyion controls the “quality” of plasma created with the ability to manage the type of charged particles produced with specificity.

The Oxyion sanitizing system consists of a Modulated Dielectric Barrier Discharge (MDBD) Technology. The custom made HFM & SRM modules combine a frequency and voltage modulated pulse power supply circuit that drives a sealed Dielectric Barrier Discharge chamber array. The Oxyion technology adapts to the environment without changing the temperature or humidity.

The specific Oxyion technology process is approved as a chemical free sanitizer /disinfectant according to USDA National Organic Standards, with no restrictions to people or products. (#2857 Oxyion, Sanitizers/Disinfectants, un-restricted use) This ambient air driven process generates a specific non-thermal plasma with several reactive sub-compounds of oxygen and peroxides, including hydrogen peroxide and hydroxyl radicals that collectively produce a synergistic effect to actively eliminate airborne and surface-level microorganisms.

When Microorganisms Encounter Oxyion’s MDBD Technology

Supplemental Reduction Process

Oxyion’s MDBD process generates a controlled blend of oxygen-based compounds that interact with microorganisms in the environment and help reduce their overall presence. The primary compound produced is hydrogen peroxide (H₂O₂), a stable molecule recognized for its role in supporting environmental hygiene.

These compounds are formed through natural oxygen reactions, similar to biological processes in which human immune cells produce hydrogen peroxide to help defend against microorganisms.

Over time, the reactive byproducts revert safely to water and oxygen, leaving no chemical residues.

The result is a continuous and balanced supplement to existing cleaning, ventilation, and hygiene practices—all under controlled conditions to ensure safe and consistent operation.

Advanced Air Process for Cleaner Indoor Environments

Oxyion technology is designed as an advanced enhancement to indoor air handling, ventilation, and HVAC systems. Ambient air passes through a specialized reaction chamber where it undergoes a controlled process that supports improvements in indoor air quality. The treated airflow is then seamlessly delivered into the designated areas.

Each system includes integrated smart controls that continuously manages performance. These controls adapt dynamically to environmental conditions, ensuring balanced operation and consistent results—without the need for added chemicals.

This approach provides a robust, reliable, and safe environmental air treatment solution that operates in alignment with recognized international standards and guidelines.

Disclaimer: Oxyion technology, products, and services are designed for industrial applications focused on helping to filter and reduce levels of general environmental contaminants in controlled environments. Oxyion does not make, nor imply, any claims or guarantees regarding the prevention, treatment, or mitigation of disease caused by viruses, bacteria, or other microorganisms.

The technology is intended solely as a supplementary intervention to support existing hygiene and air quality practices. It is not a substitute for routine cleaning, disinfection, or compliance with guidelines issued by provincial/territorial public health authorities, or other applicable regulatory bodies.

Oxyion assumes no liability for losses or damages arising from claims, use, or misuse of the technology. Any references to performance are based on academic research, independent studies, or company-funded studies, which are available upon request.